ODM Management- Procedures And Precaution

Step 1- Clarify Your Needs and Requirment

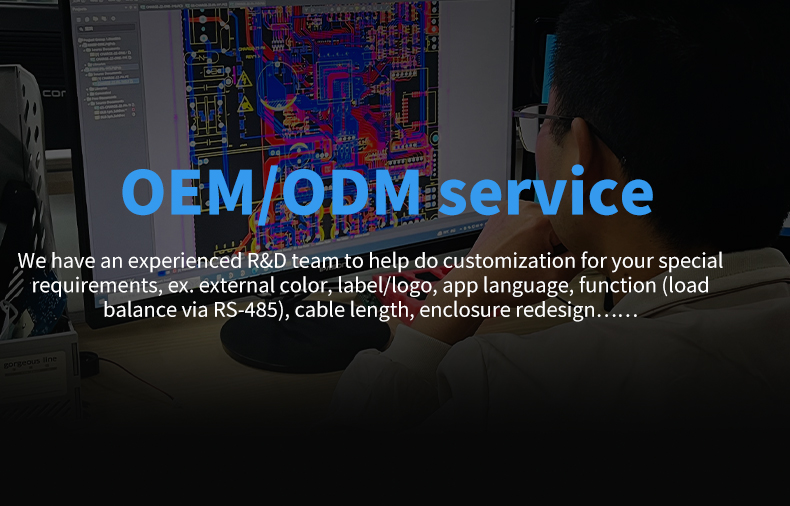

When you are planning to start your own brand and customize your own design of EV Charger, you may have or need to have clear mind in requirements and market position for your product and brands you want:

1. Who is the your target consumer group ?

2. What their mian focused functionality ?

3. Product Positioning or brand Positioning ?

4. Sales Channels : online or distribution network ?

5. Target Price and Cost

... ...

The clearer your requirements are , the more accurate the direction of customization will be , if you don't have very clear vision in mind or if you are new to this field, you can ask us to give corresponding product suggestion based on your current idea. Or below information may help you think better about your business.

Who is suitable for ODM Service?

Most of the newcomers to EV Charging field like ODM service and build their own brand, but who is really suitable to customize a new product from the very beginning?

1. The one who have a very clear knowledge and understanding of EV Charging Stations and have very rich experience in contact with some teams of EV charging stations.

2. A company with mature sales team, stable sales channels and clear sales planning, no matter online like Amazon, ebay or Walmart , or distribution sales network.

3. Know your customization needs and have clear sales target market and sales maps.

4. Have a positive mind and view about the electric vehicle industry and have confidence in the rapid growth of the charging stations market.

5. Companies that own or plan to own their own EV charger brand.

6. The planned annual sales volume is more than 2000 PCS.

If you can match 4 conditions of above , you are suitable to start the ODM customization service.

Step 2- Confirm the Details

Generally speaking all these points you shall consider in a ODM customization service

1. Appearance or Enclosure design : you can give us some features or sketches.

2. Functionality : Display, APP, Bluetooth, 4G, Dynamic load balance, LED light strip etc.

3. Electric parameters: Power, IP rating, RCD types, Protection, Dimensions etc.

4. Certification : TUV, BV, RoHs, Reach, CE, UL, ETL, FCC, etc.

5. External Features: LOGO, Color, Material texture, stickers, etc.

6. Packaging details: User manual, package design, labels, etc.

7. Customization Period and Cost : 5-7 weeks, 20000- 50000 USD including design cost, moulding cost , certification cost

Before you decide to start the cutomization, you need to know that this procedure is quite a long period you are going to have a prediction for this. Generally it will take 5-7 weeks for the first edition comes out, and it also take a few weeks to discuss the changes of the design.

Confirmation of the deails is very important before start the contact. We also will provide a customized requirements form to help you.

Step 3- Sign the Contract

After confirmed all the details, the formal develoment contract can be signed , which mainly will indicate the requirements of the customizaed products, the project period and payment method. Thhe customization project officially begins after the contract is officially signed.

- Once the the customization project officially started, generally no adjustments can be made to the confirmed details, once any changes will lead the delays of the period. This is always happening when a fresh and brainstorm comes. But we would suggest not to do so.

- The after-sales service will be indicated in the contract.

Step 4- Customization Starting

After the contract is signed, and the following points will be very important during the whole project:

1. Structure and mold customization: the first sample will be approved by 3D printed sample

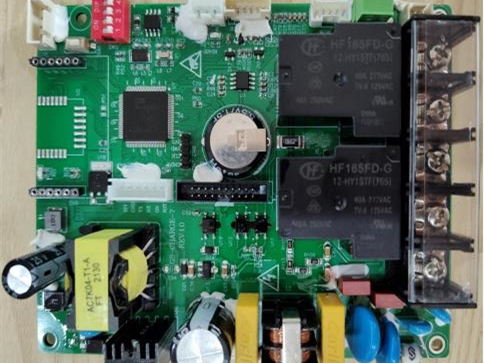

2. Circuit board design and software programming: The first sample will be used the manual welding PCBs for function approval.

3. After the sample has been approved, the mold also will be produced. The mold once confirmed, if any changes during the production, there would have additional fees. So the decision shall be made carefully during sample check.

Step 5- Sample Test

There would be two sample check here : The first sample will be 3D printed sample for design check ; The second will be molded sample with complete function. All these features shall be checked:

1. If the material texture and appearance of the product is compliance with the design.

2. If the IP degree, waterproof, workmanship of the structure satisfy you.

3. If the circuit board and electric components are wired properly.

4. If the electrical performance of the EV charger can meet the standard.

5. If the sample charger has the function we indicate in the contract. the most important is charging the electric car properly.

6. If all the protection can be triggered normally.

Step 6- Small Batch Proudct Test

No matter the 3D printted sample or molded sample, they are assembled by development engineer manually. It's not the standard product. Small batch production will be assembled at the production assembly line. And the small batch production will follow the development test one by one by development engineers to check the stability , failure rate and fault analysis.

Some time the sample test is okay, but during the small batch test, various failures will come out, so these period is very important for a new design product. Generally these period will decide the failure rate for the massive production. Normally the development test has higher standard with extream conditions to find the various problems may happen. So the engineers can optimize the design to make the new EV Charger more stable and reliable.

Step 7- Certification Procedure

After the small batch production and test period finished, the products almost are stable. So the certification process can be started. Generally, certification period will take different period. For example, TUV CE, it will take 3-4 months from the first batch of test samples delivered. For UL or ETL, it will take 4-6 Months from the first batch of test sample delivered, or even longer due to the appointment of the Labs.

Generally factories with relevant experience can pass the test and get the report for 2-3 times. on the contrary, it may need 5-6 times or even more. It depends the engineer 's familiarity and professon with the standard and test methods.

Step 8- Project Acomplishment

After the long period of certification, when you get the certification, which means the cutomized product are finished and settled from the hardware and functions. Software can be upgraded from time to time to optimize the user experience. And the product can be selling and promoting and massive production.

The package design, label design, and user manual design will be finished during the process of the certification process. During this long period, client will have very full plan for how to market and promote the EV charger, and inventory plan. All the customized materials and components need time to be prepared. And the factory also need to make the production plan to maintain a safe material inventory according to customer's sales plan.