Certain rare earth elements and metals are in high demand globally as automakers ramp up production of electric vehicles instead of internal combustion engine-powered cars and trucks. One challenge in producing electric vehicles is finding enough raw materials, which can be difficult to source and sometimes scarce. One of the key raw materials for making electric vehicle batteries is lithium.

Germany has announced that it has discovered massive lithium deposits under the Rhine and plans to mine the key material. According to the authorities, the deposits under the river are enough to build 400 million electric cars. The Upper Rhine Valley in the Black Forest region of southern Germany is located in an area approximately 186 miles long and up to 40 kilometers wide.

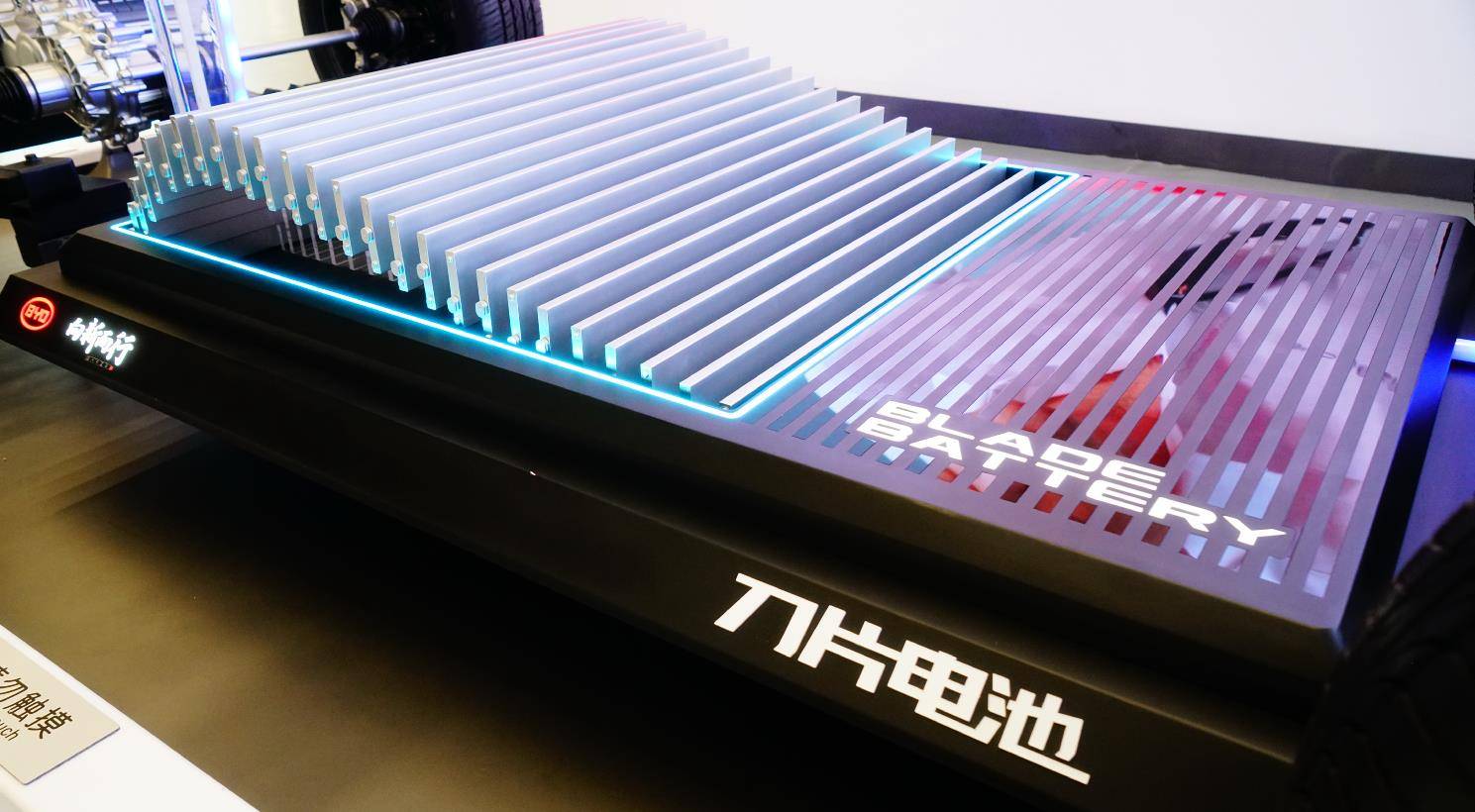

(The picture is only for reference)

Lithium is in a molten state, trapped in boiling underground springs thousands of meters below the Rhine. If estimates of the size of the lithium deposit are accurate, it would be one of the largest in the world. If the material can be successfully mined, it would reduce Germany's reliance on imported lithium, and early talks are already underway with carmakers.

Authorities who want to mine the key material fear possible local opposition to mining operations. Most lithium deposits so far have been in remote areas of Australia or South America, where there is little population opposition to mining operations. Vulcan Energy Resources plans to invest about $2 billion in geothermal power plants and facilities to extract lithium.

(The picture is only for reference)

The company believes it can extract 15,000 tonnes of lithium hydroxide per year at the two sites by 2024. The second phase will begin in 2025, targeting an additional three facilities with an annual production capacity of 40,000 tonnes.

Comments:

As known, all the well-known brands of cars like Volkswagen, Mercedes-Benz, Audi, BMW, etc. in Germany turned to electric car, and the most big problem is the production and delivery problem in 2022. People who bought an electric car has to wait 12 months even 18 months for longgest. The battery raw material leackage or price arising is one of the key points of this delays. Due to the delays of EV delivery, the installation needs of EV Chargers also delayed for these future electric car owners. But now this found will help solve a big problems for these electric car manufacturers in Germany, even in Europe. We think in 2023, the ev charger business in Europe will recovery and booming. The electric car pecentage in Gemany is less than 30%. The total passenger cars on the road is more than 80 millians. So this huge lithium founding will help Germany to speed up the electric process. So it shall be a great news for EV charger.

Green Science is a professional manufacturer of EV Charger in China. We have a experienced technical team and production team to ensure the quality and stability. Please contact us to get more infor for the EV Charging Station business.

Post time: Dec-07-2022